Summary

Höegh Evi, together with Wärtsilä Gas Solutions and partners, has successfully piloted the world’s first ammonia cracker designed for floating terminals. This breakthrough enables industrial-scale hydrogen production onboard, using ammonia transported by ship as an affordable, scalable energy carrier.

Challenge

The EU aims to consume 20 million tonnes of renewable hydrogen annually by 2030. Half of this is expected to be imported, largely from regions where hydrogen is produced with abundant, low-cost renewable power. However, transporting hydrogen is difficult due to low volumetric energy density and risk of losses of vaporization.

Ammonia crackers being built onshore face a number of challenges: limited available land in congested port areas, high construction costs, long timelines, and complex permitting processes.

Solution

Floating terminals offer a pragmatic, space-efficient and cost-effective way to quickly expand Europe’s hydrogen infrastructure.

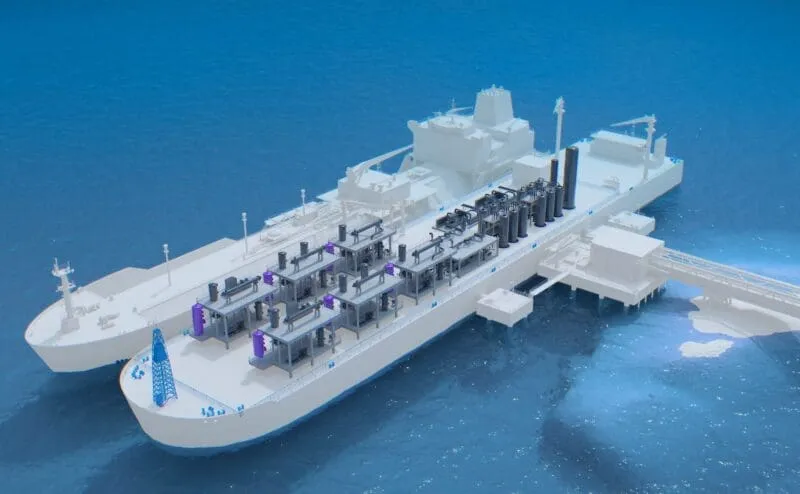

Marine carriers transport clean hydrogen from overseas in the form of ammonia, which is received by floating terminals. The ammonia is then “cracked” back into hydrogen through a warming process without producing emissions. The energy is delivered into the European hydrogen backbone where it is available for industrial consumption.

Höegh Evi’s modular design also allows adaptation to market needs while maintaining energy security. The industrial-scale ammonia cracker can be integrated into hybrid floating storage and regasification units (FSRUs) or installed on dedicated floating hydrogen terminals, delivering large volumes of baseload-ready hydrogen at a highly competitive price.

The project has received approximately EUR 5.9 million in funding from the Norwegian Government’s green platform programme, representing approximately 50% of the total budget. The ammonia cracker was constructed at Sustainable Energy’s Norwegian Catapult Center in Stord, Norway. Additional partners in the project include the Institute for Energy Technology (IFE), University of South-East Norway, Sustainable Energy and BASF SE.

Impact

10

Million tonnes of green H2 per year by 2030

21000

tonnes annual H2 capacity

>10000

10,000 – 120,000 Ammonia storage range in m3

Other projects